100+ Years of Manufacturing Excellence

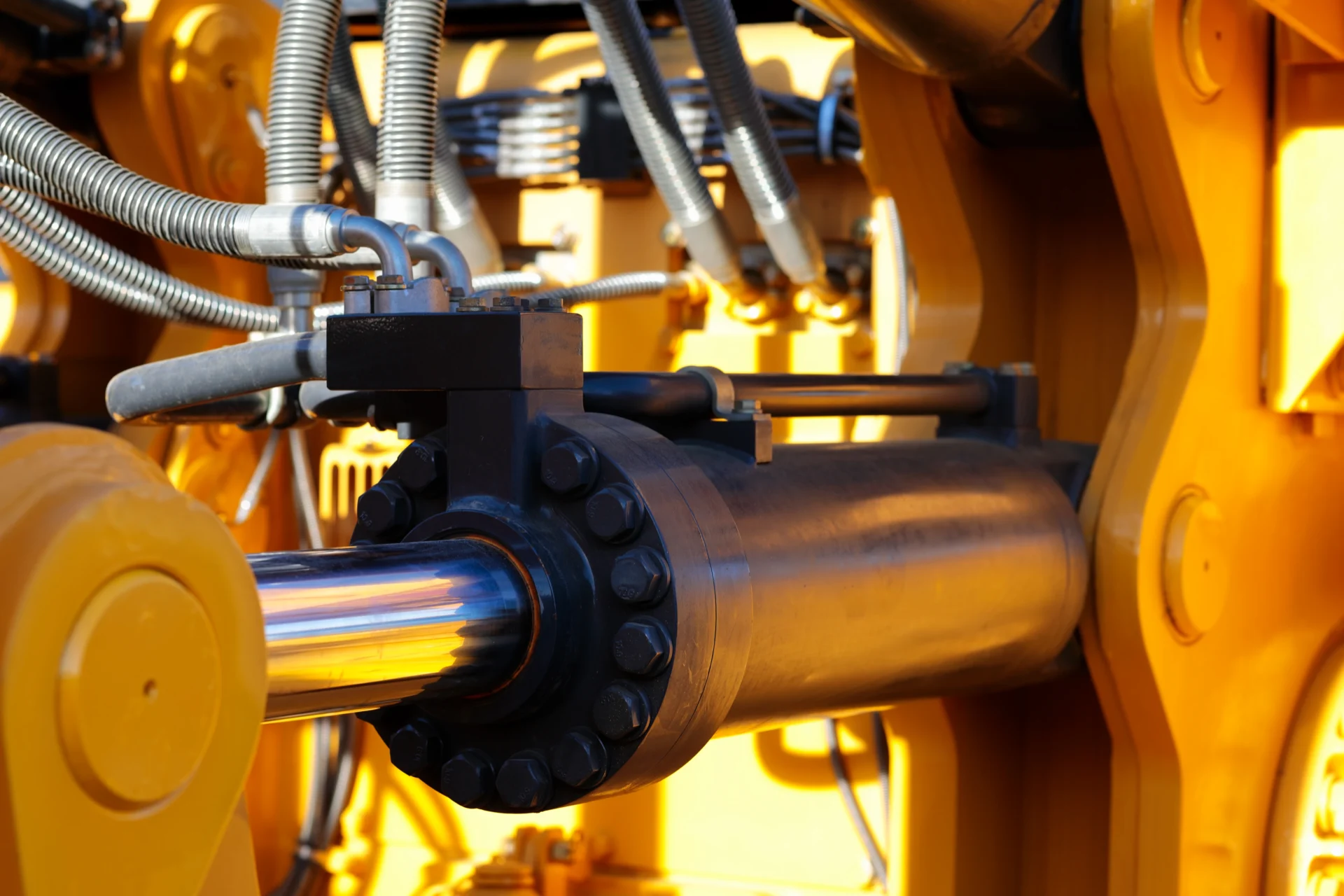

AD Piston Ring, LLC is a Cleveland-based manufacturer specializing in cast iron and bronze piston rings for hydraulic and pneumatic applications. Founded in 1921, the company has a long history of producing precision-engineered rings for industrial use. They also offer stainless steel plunger rings, catering to various mechanical needs. With a commitment to quality and service, AD Piston Ring continues to be a trusted name in the industry.

AD Piston Ring, LLC has a rich history dating back to 1921, when it was founded in New Haven, Connecticut to manufacture parts for the automotive industry. In 1925, the company relocated to Cleveland, Ohio, where it became a key player in piston ring production for ships, tanks, and steam locomotives.

Over the decades, AD Piston Ring evolved to focus on industrial applications, including hydraulic and pneumatic systems, compressors, and die casting machinery.

The company's mission is centered on precision, quality, and service. They manufacture cast iron rings up to 30", bronze piston rings, and stainless steel plunger rings, with a commitment to meeting industry standards and customer specifications.

Our Expertise

We specialize in manufacturing high-quality piston rings, including:

Cast Iron Piston Rings

Manufactured to order, our cast iron piston rings range from 1″ to 30″, made to exact customer specifications.

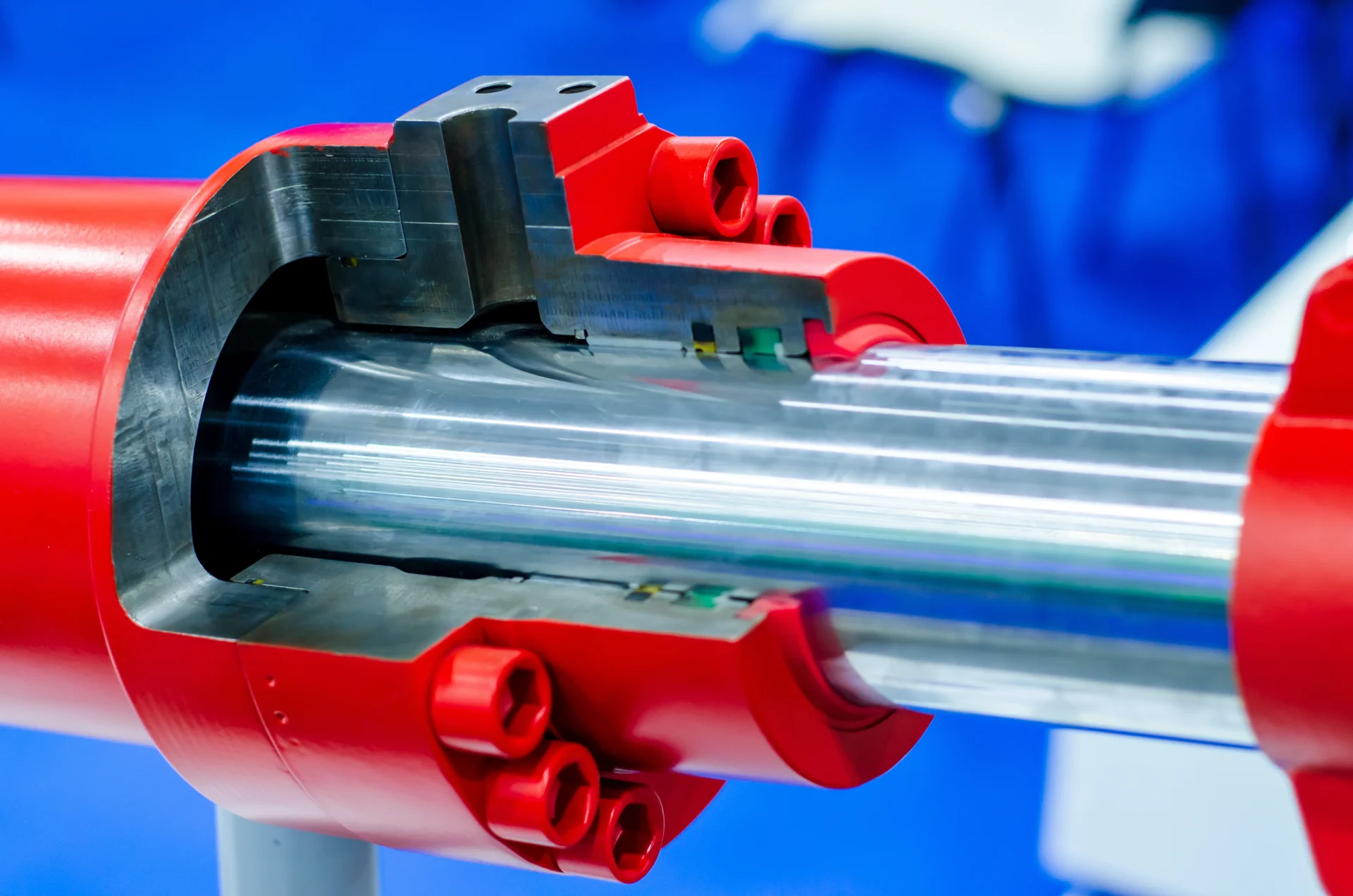

Stainless Steel Plunger Rings

We offer stainless steel plunger rings ranging from 3/4″ to 7″. Popular sizes are stocked for immediate delivery.

Why Choose Us

A Legacy of Precision and Innovation

Founded in 1921, Auto-Diesel Piston Ring Company began its journey in New Haven, Connecticut, with a clear vision to manufacture high-quality automotive parts. Over the years, the company expanded its operations, evolving with the needs of the industry and cementing its place in the manufacturing world.

Our Growth Journey

Relocation to Cleveland

In 1925, Rolland D. Smith moved the company to Cleveland, Ohio, where it continued to grow and diversify. The company was officially incorporated in Ohio in 1941, with Albert Sawyer serving as the first president and Rolland Smith as General Manager.

The 1940s and Beyond

The 1940s marked a pivotal time for the company. During World War II, Auto-Diesel played a crucial role in the defense effort, providing piston rings and gaskets for ships, tanks, and steam locomotives. The company operated three shifts around-the-clock to meet the urgent demand for these essential parts.

A Shift in Product Focus

However, as the war ended and industries shifted, so did the company’s product line. Auto-Diesel evolved from automotive parts manufacturing to specializing in piston rings and seals for a variety of industrial uses such as hydraulic and pneumatic applications, compressors, and stainless steel plunger rings for the die-casting industry. The development of stainless steel plunger rings helped protect plunger tips on zinc die casting machines, a critical innovation that continues to serve the industry today.

A New Era

In 2015, Auto-Diesel Piston Ring was acquired by Bob Lee and a group of local Cleveland investors. With over 100 years of combined manufacturing experience, the new ownership focused on revitalizing the company while honoring its legacy. To reflect the shift in focus toward industrial applications, the company transitioned its name to AD Piston Ring.

Commitment to Excellence

AD Piston Ring is committed to producing precision products at competitive prices. With a strong emphasis on service and quality, the company manufactures a wide range of products, including cast iron piston rings (1” to 30”), bronze piston rings, and stainless steel plunger rings (3/4” to 7”). All cast iron rings are custom-made to customer specifications, while popular sizes of stainless steel piston rings and seals are stocked for immediate delivery.

The Future

AD Piston Ring LLC continues to invest in its future, with ongoing capital improvements in manufacturing, including new machinery and testing equipment for enhanced quality control. The company also prioritizes employee development through training programs to ensure the continued growth of its most valuable asset: its people.